The Danish BUKH DV10 is a single cylinder, four stroke marine diesel engine. It was available in 3 configurations;

- DV10 M – Manual Start Only

- DV10 ME – Manual and Electric Start

- DV10 SME – Saildrive version

General Description

BUKH DV10 and DV20 are single- and two-cylinder water-cooled 4-stroke diesel engines operating on the pre-combustion chamber principle with 2-stage combustion. The engines are specially designed to comply with the heavy demands made on stability, safety and environment now.

Cylinder Head

The cylinder head is made from highly alloyed special cast iron which is most resistant to thermic and mechanical loads. Each cylinder unit is fitted with an exhaust valve and a suction valve respectively. The very big suction valve secures together with the aerodynamically designed exhaust and suction manifolds a correct flushing of the cylinders.

Both valves operate in replaceable valve guides of special cast iron which ensures high wearing qualities. The valves are fitted in the cylinder head. The replaceable valve seats are shrink fitted into the cylinder head and they are made from heat resisting special steel with high mechanical wearing quality. The valves are also made from special steel with high strength and toughness and great importance has been attached to resistance to heat.

Crankcase

The crankcase is made from special cast iron and is provided with strong ribs which give great toughness and strength together with the special tunnel-shaped bore to the crankshaft.

Crankshaft

The crankshaft is made from die-forged chrome steel. Each crankshaft is fitted with special counterweights on the crank throws. These weights are balanced in order to obtain smooth running of the engine. Each crankshaft runs in two main bearings (on both DV10 and DV20) and in an intermediate bearing as well (DV20 only). The bearings are made from steel with a tin aluminium alloy which can stand up to high pressures. The crankshaft is steered in axial direction by turned surfaces on the crank throws and contact faces on the end cover (DV10) and the intermediate bearing (DV20). On the surface the engine is tightened by means of oil seal rings fitted in the end covers.

Flywheel

The flywheel, made from cast iron, is bolted on the crank- shaft in the engine front end. It is large-dimensioned to secure steady operation of the engine. The flywheel is fitted with a V-belt groove for driving the electrical equipment of the engine and cooling water circulating pump, if any. Further, the flywheel may be fitted with extra three-groove V-belt pulley or flat belt pulley.

Connecting Rod

The connecting rod is die forged with H-shaped section. The bearing cap forms part of the connecting rod itself. The base of the bearing is separately adapted for the individual connecting rod and is guided in proportion to this by two steel balls. The connecting rod bearings are made from steel shells with a tin aluminium alloy and are fastened in the bearing cap and the base of the bearing with two Allen steel bolts. The bearing for the piston pin consists of a special bronze bushing.

Piston and Cylinder Liner

The pistons are made from a light alloy. The combustion chamber is shaped in the piston head. The pistons are fitted with three compressing rings and an oil scraper ring. The piston pin, which is floating, is hollow and made from hardened steel. The piston pin is locked in axial direction by circlips.

The cylinder liner is made from spun cast iron with a high carbon content which gives high wearing qualities. The cylinder liner is guided in proportion to the crankcase with a recess in the top and a conical bore in the bottom. The tightening results from the specially made cylinder-head gasket and two O-rings in the conical bore.

Camshaft

The camshaft and the cams for activation of the suction and exhaust valves are cast in one piece in order to achieve as high strength as possible. The cams are case-hardened for great stability and resistance to wear.

The camshaft is driven by a gear-wheel on the crankshaft and by one shrink fitted on the camshaft itself. These two gear-wheels are marked in proportion to each other, and it is necessary for the operation of the engine that this marking is observed with the greatest accuracy at removal and assembling. The fuel pump cam is fitted in connection with an injection timing which alters the injection time according to the engine revolutions.

Lubricating Oil System

The engine is pressure lubricated by means of a lubricating oil pump of the rotary type (Eaton pump with high efficiency). The pump is driven by the camshaft and is placed.on the rear end cover of the engine. The lubricating oil pressure is controlled by a spring-loaded pressure relief valve.

Cooling Water System

The cooling-water temperature is thermostat-controlled which gives a constant and effective operating temperature. The engines can be delivered with either direct or indirect cooling.

Fuel System

The fuel is led to the engine from the fuel valve placed in the cylinder head. This valve gets fuel under high pressure from the fuel pumps which are activated from the camshaft. The fuel pumps are supplied from the fuel tank via a lift pump and an effective filter.

Electric Starter Motor

In 1974 the gear rim starter replaced the dynastarter in both the DV10 and the DV20 engines. In the DV10 engine, #89157 and up had a gear rim starter. In the DV20 model, engine #93638 and up had a gear rim starter.

Notice that the starter gear is normally dis-engaged while the motor is running or stopped. When power is applied to the starter motor, a Bendix gear forces the small pinion gear to engage with the gearing on the flywheel. If you can hear the starter motor spinning and the flywheel is not turning, then your Bendix may be the problem.

How heavy is the BUKH DV10 Engine?

The different models of the BUKH DV10 Marine Diesel engine weigh between 140 kg (308 lbs) and 160 kg (352 lbs). The dry weight of the Type-M engine equipped with hand start only is 140 kg (308 lbs). When the engine is equipped with the electrical start option (Type-ME), the dry weight increases to 150 kg (330 lbs). The electric start engine equipped with a sail-drive (Type-SME) weighs in at at dry weight of 160 kg (352 lbs). Lubricating oil, coolant and any alternator upgrades will add to this weight.

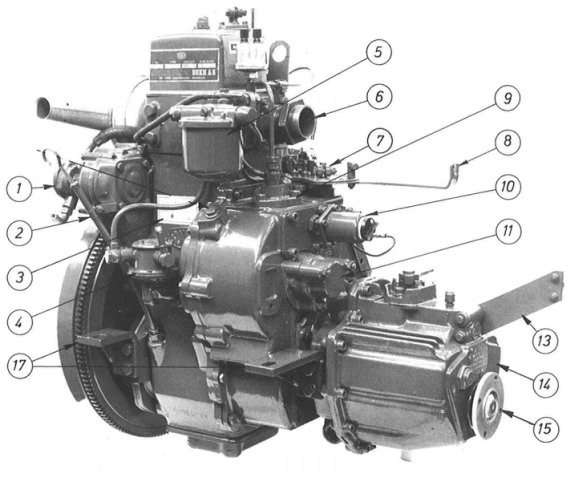

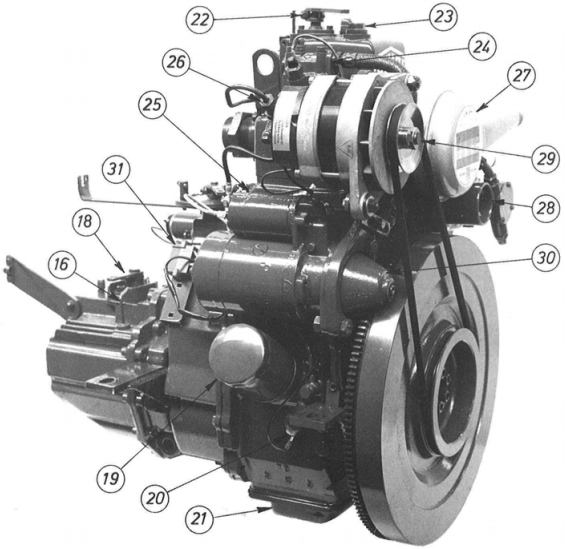

Components of the BUKH DV10

- Cooling water pump

- Oil dipstick

- Water drain from engine block

- Fuel lift pump with manual priming

- Fuel filter

- Exhaust pipe

- Regulating lever

- Bracket for remote control of regulating lever

- Fuel pump

- Electro-magnetic stop-coil

- Lubricating oil pump

- Bracket for remote control of reversing gear

- Reverse-reduction gear

- Coupling flange for propeller shaft

- Oil dipstick for reverse-reduction gear

- Reversible engine mountings

- Gear lever for reverse-reduction gear

- Lubricating oil filter

- Oil pressure switch

- Oil sump

- Decompression lever

- Oil filling plug

- Cooling water thermostat

- Zinc rod

- Nozzle holder

- Air cleaner with silencer

- Raised hand start

- Alternator

- Starter

- Electric multi-plugs

Specifications of the BUKH DV10

| Working Principle | 4-Stroke |

|---|---|

| Number of Cylinders | 1 |

| Cylinder Bore | 85 mm |

| Cylinder Stroke | 85 mm |

| Volume | 0.482 litres |

| Compression Ratio | 21.5:1 |

| Output Power (at 2000 rpm) | 6.4 HP |

| Output Power (at 2400 rpm) | 8.4 HP |

| Output Power (at 3000 rpm) | 10 HP |

| Max Torque | 2.5 Kpm (at 2700 rpm) |

| Engine Rotation Direction | Anti-clockwise (looking forward) |

| Idling Speed | 900 - 1200 RPM |

| Max Inclination (fore and aft) | 15° |

| Engine Weight (DV10 M) | 140 Kg |

| Engine Weight (DV10 ME) | 150 Kg |

| Engine Weight (DV10 SME) | 160 Kg |

Video: Click to watch a short video of a BUKH DV10 running

Do you own and maintain a BUKH DV series Marine Diesel Engine? Check out our Almanac of issues that BUKH owners have solved in the past.

- BUKH DV20 Injector Leak Problem

- BUKH DV10 Exhaust Elbow Longitudinal Cracks

- BUKH DV20 – What is this sensor?

Do you want to get future BUKH DV Series Almanac articles straight to your inbox? Sign up to our BUKH DV Series Owners’ Group today and we’ll make sure that you’re first to see them. And we definitely won’t share your email address with anyone else.