An important part of the annual maintenance list is inspection of the water jacket anode in your engine. Using salt water as the primary coolant for your Yanmar 1GM or 1GM10 engine simplifies the design tremendously but it does mean that corrosion is a constant threat. Your only defense against your engine corroding away from the inside is the single anode which is located inside the water jacket of your engine. Regular checking and replacement of this part is essential maintenance of your Yanmar GM1 series engine.

Diesel School: Click to learn more about Zinc Anodes

This job is made a little less attractive by the inconvenient location of the anode cover on the GM1 – it is located just below the head and it’s necessary to partially remove the alternator to get any reasonable access to the anode cover.

TECHNICAL DETAIL: Yanmar 1GM Anode part Number: 27210-200200

Partially remove the alternator

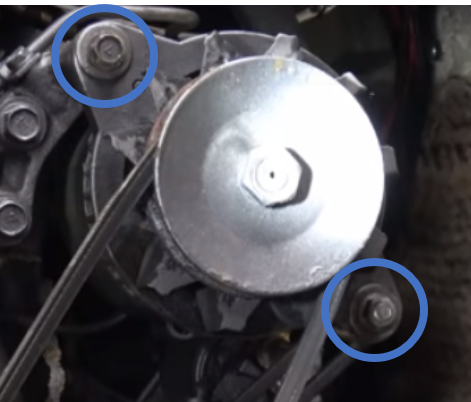

The alternator on the 1GM is held in place with two large bolts (as shown). The lower right-hand bolt in the photo is used to tension the belt correctly. Loosen that a couple of turns and then remove the upper left-hand bolt (in the photo). This will allow the alternator to swing out of the way and allow access to the engine casing.

Remove the anode cover

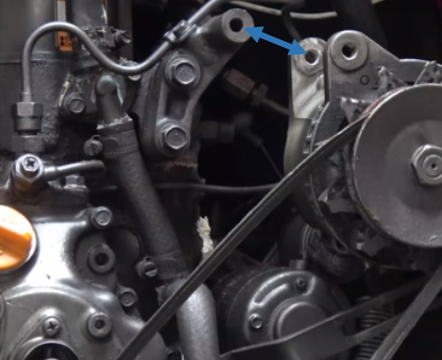

With the alternator no longer blocking access, you should now be able to see the anode cover on the side of the engine casing.

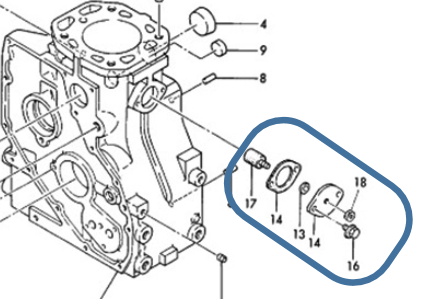

You will need to remove the two M10 bolts to remove the cover plate. With the bolts removed, it may require a gentle tap to break the seal. Water in the jacket will escape. The corroded anode is attached to the plate with the central retaining nut shown in the picture above.

Holding the plate in a pair of wide mouth pliers, remove the retaining nut screw off the old anode. If you do not have a new rubber washer, then salvage the old one. The plate should be sanded down with some wet and dry sandpaper – remember that good electrical connectivity is essential for the anode to do its job.

Fit the new anode to the plate

Next, fit the new anode to the plate with a new washer and tighten the retaining nut. Remove the old gasket from the engine block. Again, this area needs cleaned down and sanded down to ensure good electrical connection between the anode plate and the engine casing (via the retaining bolts).

When everything has been cleaned, fit the new gasket to the plate, offer this to the engine and tighten the retaining M10 bolts.

TECHNICAL DETAIL: Yanmar M10 Torque Requirements: 44-50 Nm

Refit Alternator

Re-align the alternator and refit the upper bolt. Tension the alternator so that the drive belt can be deflected by about 5 mm (1/4 in) using an extended finger. When the tension is correct, tighten all the bolts and run the engine, checking for water leaks around the anode plate.