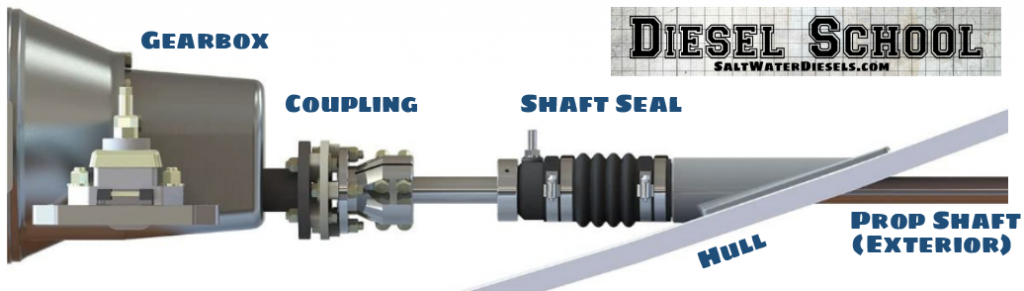

Dripless Lip Seal Stern Gland Systems

There’s an old marketing trick employed in marine stuffing boxes where a simple hyphen is intended to change the meaning of dripless [Aᴅᴊᴇᴄᴛɪᴠᴇ. drip·less designed not to drip] to drip-less [Mᴀʀᴋᴇᴛɪɴɢ Nᴏɴsᴇɴsᴇ. drip less the manufacturer hopes that it will “drip less” than rival products].

While all traditional stuffing box solutions accept an occasional drip of sea water into your bilges as the prop shaft rotates at up to 1000 times per minute, the new generation of dripless shaft seals achieve zero ingress with no packing material and less rotational resistance than traditional solutions. On the downside, however, they can not be repaired are a potential site of critical failure in your boat. They must be inspected regularly for safety reasons.

The most popular type of dripless shaft seals in small yachts is the Volvo Penta Rubber Stuffing Box, which is a fairly accurate name actually. An impressively simple unit, it combines a lip seal with a rubber hose to attach to the stern tube and contains no moving parts. It has an internal, water-lubricated “bearing” with the cooling water being naturally delivered via the stern tube. The lip seals should be greased (see below) every 200 hours of engine use and certainly at least once a year. It comes with a single, wide hose clip secured with double machine screws, to clamp it on to the stern tube.

Burping

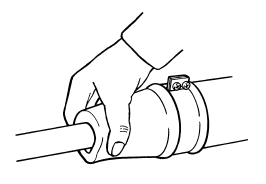

You MUST “burp” the seal each time you launch the boat. Squeeze it until water comes out. That’s it! If you forget to do that, however, you will burn out the seal with possible dire consequences.

Greasing

The Volvo seal relies on the compression of two small diameter rubber ridges (lip seals) in the forward section (i.e. closer to the engine) compressing tightly on the propeller shaft. The cavity between these lip seals should contain waterproof grease. Volvo recommend 1 cc of water repellent grease. Many owners refill this grease using a neat trick involving fast-food type plastic straws;

- Stick the plastic (definitely not paper) straw into your grease container to fill the first inch or so with grease.

- Flatten the edge of the straw, thereby sealing the grease in the straw and force the flattened straw under the first lip seal (but not as far as the second).

- Similar to a toothpaste tube, force the grease into the cavity between the two lip seals.

- Repeat at 180° offset around the shaft.

- Burp the seawater hose part in case air has been forced back.

If you ever hear a droning noise coming from the seal or the gearbox area, your seal may have run dry. If this occurs, immediately burp the seal. While Volvo recommend replacement of the shaft seal every 10 years, some owners report much longer lives without any issues. As with most things on you boat, regular maintenance is the key to longevity.

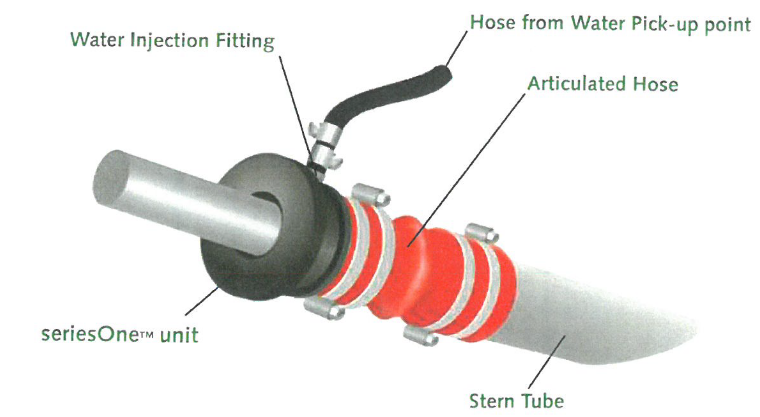

An alternative to the Volvo product is the Tides Marine series one shaft seal. It is much the same as the Volvo product with the addition of a pressurised water cooling input which is typically connected to the engine’s raw-water cooling circuit.

The minimum recommended flow rate for this is one gallon per minute at idle, so this must be carefully matched to your diesel engine.

The Tide Marine series One shaft seal was designed for single-engine vessels with stainless steel propeller shafts. This shaft seal fits shaft diameters from 7/8” through 1 1/4” in 1/8” increments. It can also be used on metric stainless shafting from 25mm through 30mm.

The manufactures stress that no grease should be used anywhere in this system.

See the detailed installation guide here.

DOWNLOAD: Click here to download the Volvo Penta Rubber Stuffing Box advertising flyer as a PDF