There are not a lot of Swedish words that have made it into other languages. Moped is one, meaning a light motorcycle. Orienteering is another. But my absolute favorite Swedish word is Smörgåsbord. This originally described a fancy type of buffet meal but has been adapted in English to mean a wide variety of something. It’s ironic, then, that problems surrounding Volvo Penta exhaust elbows in their 2000 and MD2000 series engines are caused by the smorgasbord of metals that they have been designed to sit together around the interface between the housing of the heat exchanger and the exhaust elbow.

It all started with a small exhaust leak

This Volvo Penta 2020 owner had begun to detect an exhaust smell in his sailboat when he was running the engine. A quick investigation revealed that there was a small leak of exhaust gases coming from the area between the heat exchanger and the exhaust elbow. Assuming that the gasket was leaking, he removed the elbow.

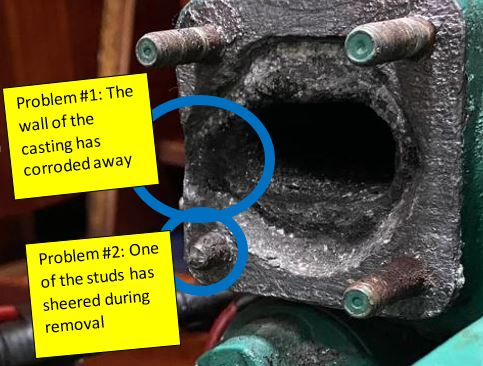

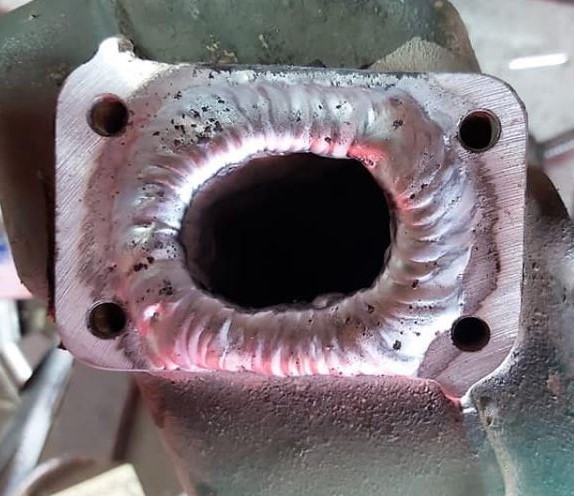

Once the old gasket had been cleaned away, three problems were obvious. The first, and most serious, issue was that the heat exchanger casting around the flange had corroded as far the wall of the heat exchanger. This is where the gases were escaping.

The second issue was that, during removal, one of the retaining studs snapped. This had obviously also been suffering from corrosion.

The third and least problematic issue was the build up of soot in the heat exchanger unit. This would need to be cleaned out before the unit was reinstalled.

All three of these are actually fairly common problems on the VP2020 heat exchanger. In an environment where hot exhaust gases are being mixed with cool salt water, galvanic corrosion occurs. Over time, electrolysis eats away at the cast aluminum of the exchanger as sure as our underwater anodes disappear over the course of a season.

From what Metal is the Volvo Penta Exhaust Made?

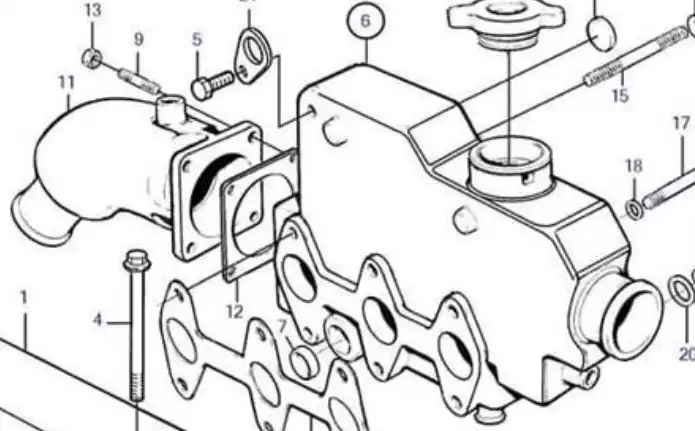

The original design has an cast aluminium heat exchanger unit (6), which is mated to a stainless steel gasket (12) with a cast iron exhaust elbow (11) on the other side. Mild steel bolt studs (9) clamp the whole thing together. In a perfectly dry environment, this arrangement might be expected to work well. And indeed, this is all upstream of the raw saltwater coolant being introduced. But it’s when we stop our engines that the damage occurs. Condensation occurs from the warm saltwater which gets trapped in the lowest point of our exhaust systems.

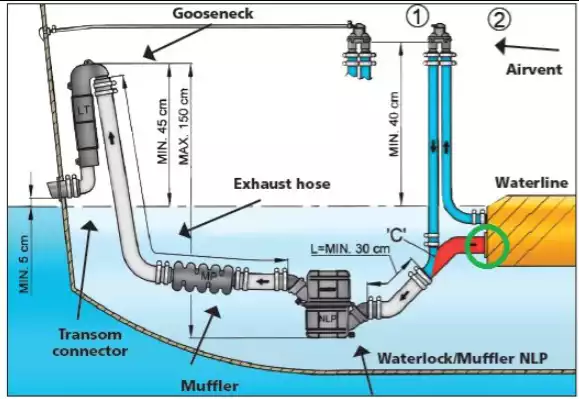

Consider, for a minute, a typical marine diesel exhaust system. The green circle represents the point where the exhaust gases leave the exhaust manifold part of the heat exchanger unit and enter the mixing elbow. The saltwater cooling circuit can be seen leaving the heat exchanger via the blue line, passing through an anti-siphon elbow and then being injected into the mixing elbow.

The rest of the exhaust system is “wet”. This prevents the rubber hose from getting too hot and the water is blown through by the high speed exhaust gases.

Then, following a long run we just stop the engine. The raw water circuit will stop at the same time as the exhaust gases. The last of the water will never be blown out of the exhaust and will pool in the waterlock to be dealt with next time the engine starts.

Some of this warm water will evaporate and condense back up the exhaust at the multi-metallic joint between the heat exchanger and the elbow which is hot and sulfurous. This liquid electrolyte will now allow galvanic corrosion to occur and the least noble metal, aluminum in this case, will quickly erode.

Exhaust Elbow Studs

These studs removed from a Volvo Penta 2010 exhaust elbow are M8 x 30mm. You will note, however, that they have a shoulder around a third of the way along. If you can’t get your hands on Volvo Penta replacements, you could use a length of high-tensile steel M8 threaded rod. Cut to size and insert into the engine block with two nuts locked together.

The flange nut on the right hand stud is the original. Tempted as you might be to replace it with stainless (like on the left), I would not. Given the mix of metals in this area, I’d stick with black-oxide coated high-tensile steel parts.

Repairing the Corroded Heat Exchanger Flange Wall

The only way to repair the corroded wall of the heat exchanger is to build up new metal. The new metal needs to be welded on to the existing metal and then machined back to a flat surface. You’ll probably want to remove the heat exchanger from the main engine at this point. Next, the studs must all be removed. A combination of heat and penetrating oil will make this job easier. And save yourself some time and effort – get the good stuff like KROIL rather than WD-40. [check the current price of KROIL on Amazon.com]

Once the studs have been soaked in penetrating oil for a few days, lock two nuts onto the threads and draw the studs out of the heat exchanger body. If they are still tough to move, apply a bit of heat to the stud using a torch.

How to prevent this from occurring in future

As most VP owners know, parts are very expensive for these engines. One simple way to minimize this galvanic corrosion, if not fully eliminate it, is to change the material of the gasket. Stainless promotes the corrosive action. Many modern gasket materials can withstand very high temperatures while electrically insulating the elbow from the heat exchanger unit. These are widely available as after-market products. If you have never changed the OEM stainless one, I’d add this to your to-do list for the winter.

A smart skipper learns from the lessons of others.

In our Volvo Penta MD2000 Series Almanac section, we have a series of previous questions and queries from MD2000 series engine owners along with answers. Many of these have been adapted from discussions on the “Volvo Penta Marine Engines owners group” Facebook group which is a fantastic resource for getting technical help.

Do you want to get future VP MD2000 Series Almanac articles straight to your inbox? Sign up to our VP MD2000 Series Owners’ Group today and we’ll make sure that you’re first to see them. And we definitely won’t share your email address with anyone else.

Recent and Current Owner’s Group Articles